Tamper-Proof Marking

Integrated Security Logic – Maximum Information Depth with Every Marking

Protect your products, processes, and reputation – with the market’s most compact and tamper-proof marking solution.

Implementing our forgery-proof solutions gives you control, transparency, and authenticity — everything you need to protect your brand and reputation. Ensure the quality of every part, reward the use of genuine products, and gain the ability to precisely track every component across your supply chain.

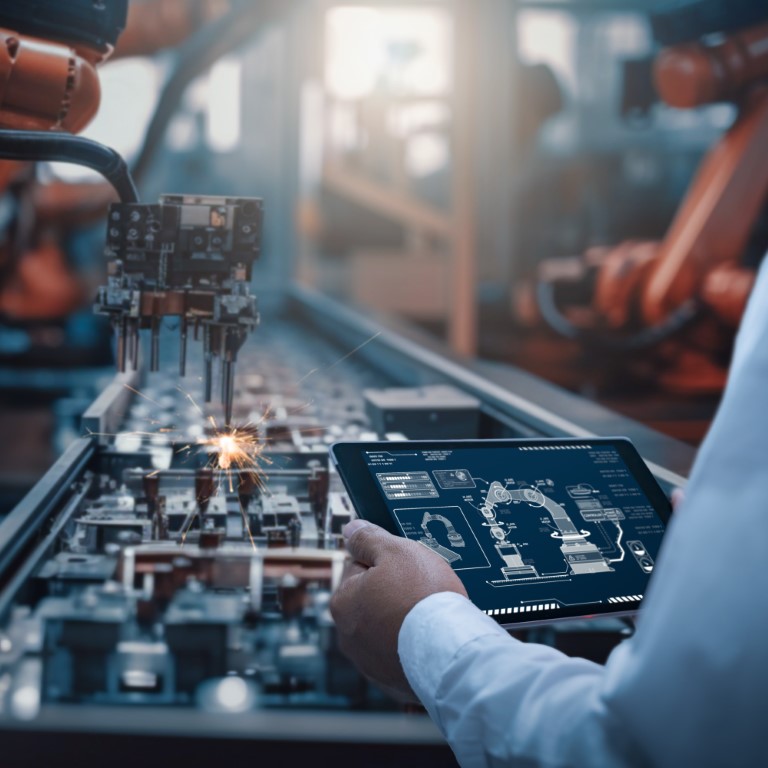

Senodis' Plug & Perform

– Fully Compatible with Existing Production Lines.

Our modular security logic enables the integration of significantly more information into each marking than conventional methods — all without the need for equipment modifications.

Why Action Is Needed

Counterfeit or tampered components lead to failures, customer complaints, and liability risks. At the same time, markets and regulatory authorities increasingly demand complete traceability.

Counterfeit Products Undermine Quality and Create Financial Risks

Counterfeits in the spare parts industry affect every level of your supply chain, drive up production costs, and compromise product integrity. Unverified components fail to meet quality standards and can lead to product malfunctions, warranty claims, and unforeseen liabilities. These risks become operational, financial, and reputational burdens for companies that rely on high-quality original parts to ensure customer safety and safeguard the sustainability of their brand. (Image © NTSB)

No Recognition or Rewards for Genuine Parts

As counterfeit parts infiltrate supply chains, the integrity of genuine components is overshadowed and goes unrecognized. When authenticity becomes difficult to verify, companies miss out on rewards and incentives for their commitment to quality — resulting in lost savings and diminished brand trust. Certified original parts build credibility, strengthen customer confidence, and add lasting value to your business.

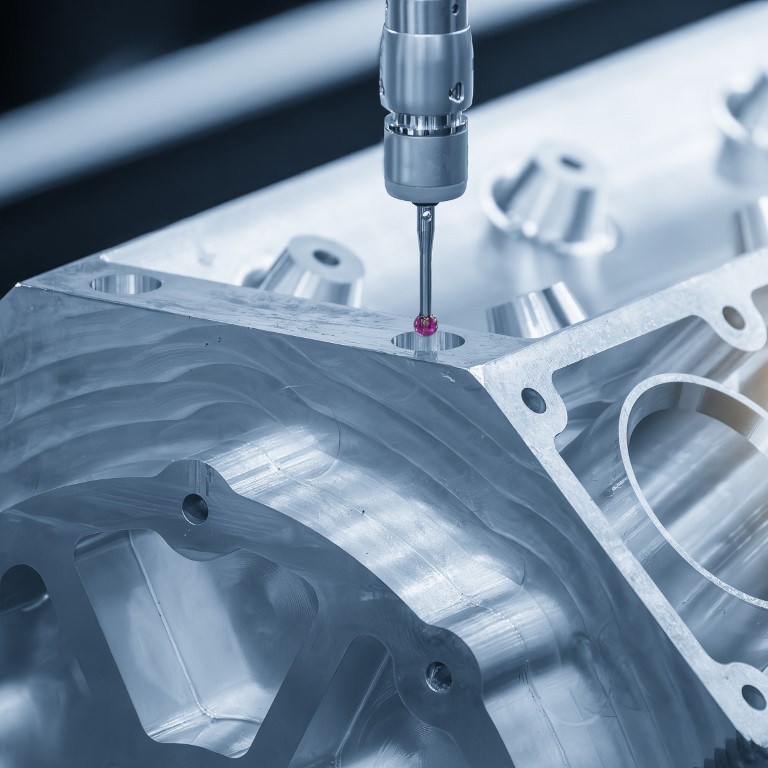

Challenges in Tracking and Traceability Due to Limited Marking Space

Tracking parts across complex supply chains is often hindered by spatial constraints. Many components lack sufficient surface area for effective marking, making it impossible to assign unique identifiers. As a result, parts cannot be accurately traced throughout their lifecycle, leaving manufacturers with limited visibility and control over the authenticity and quality of their products.

Our Solution Makes Your Part Markings Tamper-Proof in Seconds

This is achieved through our integrated security approach and software plug-ins. Your part markings remain readable with standard barcode scanners, ensuring that existing tracking and tracing systems are not disrupted. Our software enables you to verify the authenticity of your markings — protecting you from counterfeiting and its consequences.

- No changes to your existing marking line: continue using your current laser engraving infrastructure to engrave standard patterns

- Scan your codes with any standard barcode reader

- Verify the authenticity of your markings with our software

- Customize your markings with our software plug-in solution

- Significantly higher information density compared to conventional markings

What “More Information per Marking” Means for You

| Higher Information Density | Serial and batch numbers, material data, and digital fingerprints — all combined in a single code field. |

| Space-Saving & Scalable | Fits even the smallest components and evolves with your Industry 4.0 requirements. |

| Future-Proof | Upgrades via software — no new hardware investments needed. |

Benefits by Role

- Minimizes Liability Risks and Rework

- Proves authenticity to customers and auditors.

- No Downtime Due to Counterfeits

- Plug-and-play integration, implementation in less than 4 weeks.

- Traceability Down to the Serial Number

- Audit reports at the click of a button.

- GDPR-Compliant Cloud or On-Premise Option

- API Integration with ERP & MES Systems

Get Started in Three Simple Steps

- Free Code Check – We analyze your current marking process.

- Pilot Phase (4 weeks) – Proof of concept on a selected production line.

- Rollout – Scale across all relevant components and sites.

FAQ

Our licensing model scales with your needs: For each production site, you receive access to our security solution, including an initial marking volume. Additional components or lines can be activated flexibly — with no need for new hardware.

In serial production, the return on investment typically occurs within 6 to 12 months, depending on complaint rates and batch sizes.

No — the marking process remains unchanged; the additional data layers are applied within the same cycle time.

Yes — during the four-week pilot phase, a parallel code is introduced without interrupting serial production.

As of April 2025 – All information subject to technical changes.

Always One Step Ahead of Counterfeiting

Secure your products, protect your brand, and empower the people behind your business.