CeraCode® Base: Individual part marking for metals

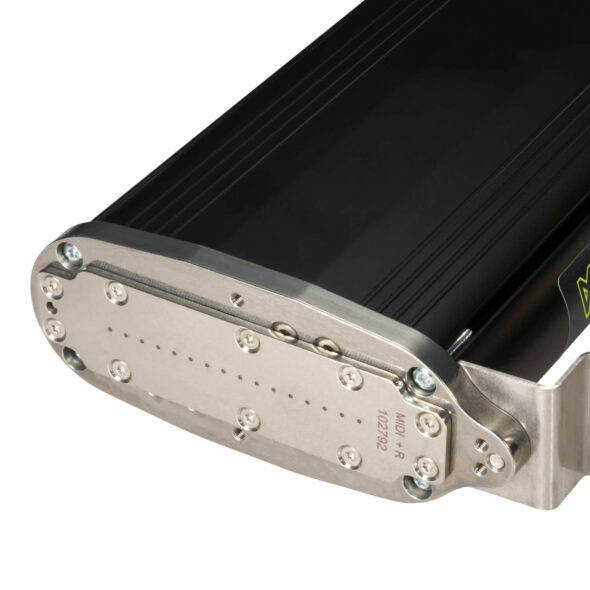

CeraCode® Base for metals is an integrated solution consisting of temperature-resistant ink, industrial printers, scanners and an intelligent data processing concept specially developed for metallic surfaces with subsequent high-temperature processes. The technology enables efficient and quickly realisable solutions for component marking and can be individually adapted to your needs.

Description

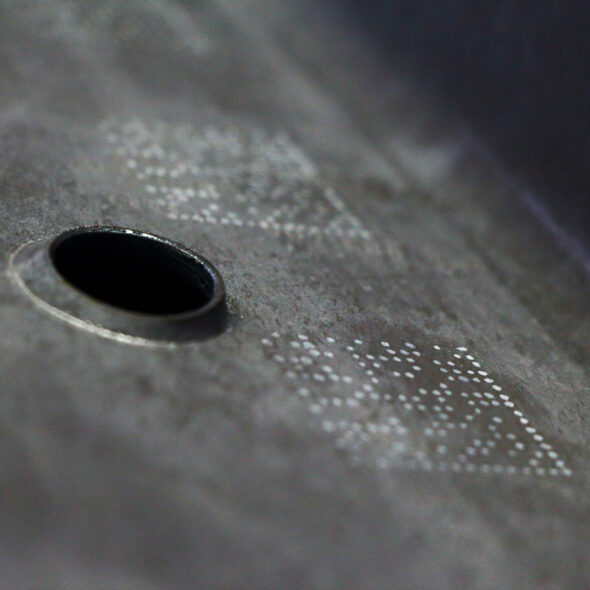

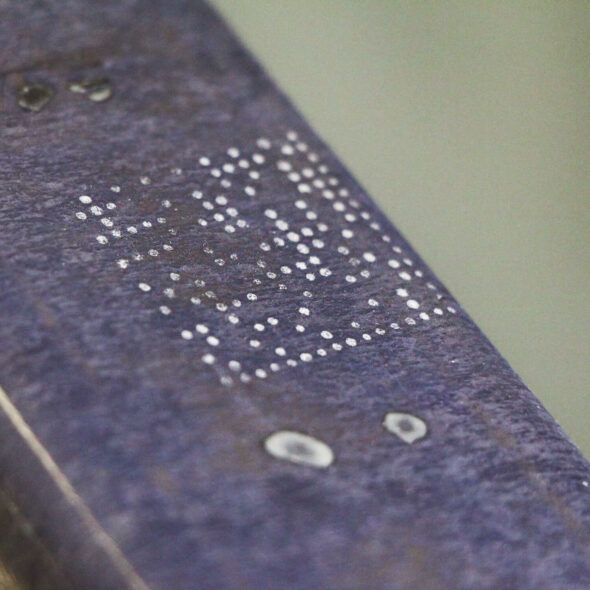

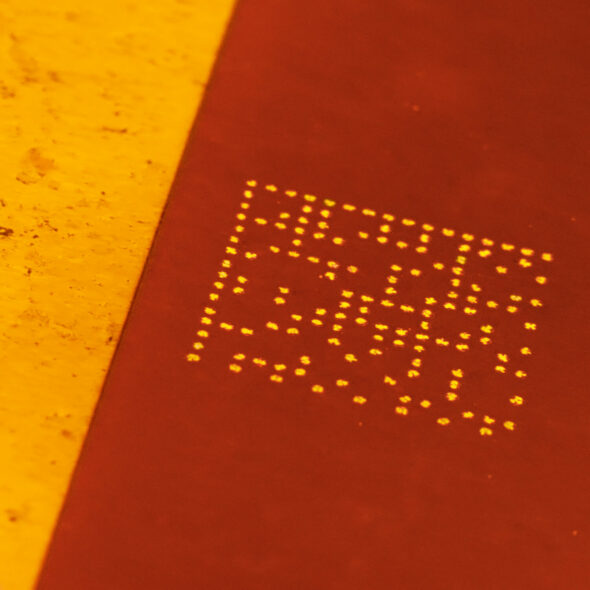

The core element of the CeraCode® process is an ink that is insensitive to aggressive environmental conditions, even at high temperatures. The ink can be printed as a DataMatrix code or plain text on different materials.

The machine-readable codes are applied using industrial drop-on-demand printers. The print image can be generated with up to 32 parallel nozzles. The ink is fixed in the oven as part of the hot forming or press hardening process at over 900°C. Thanks to an integrated, intelligent concept for data acquisition and processing, component and process data are linked and automatically analysed.

Advantages

- Temperature-resistant, customisable and machine-readable marking

- Withstands process temperatures up to over 1.000°C

- Easy integration into existing and new systems

- Seamless process data acquisition and linking of component and production data

- Immediate reduction of scrap, sorting and quality costs

Specification

The CeraCode® Base marking solution can be integrated into both existing and new systems. We offer customised integration concepts for every production line and intelligent concepts for reducing manual handling steps during operation. The position, shape and type of coding can also be customised.

We have developed the CeraCode® ink especially for the press hardening of sheet metal parts in the automotive sector. Inorganic materials ensure permanent resistance after high-temperature processes; the high contrast guarantees the machine readability of the individual component codes.

Drop-on-demand (DoD) is one of the most robust industrial printing processes. With up to 32 nozzles, codes are applied dot by dot to components. Depending on the size of the DataMatrix, more than 100 numeric characters can be integrated into the code.

CeraCode® Base has local data recording and storage. Simple integration into your IT environment is possible via standard interfaces. Data processing solutions and automated, software-controlled maintenance concepts are also supplied with the labelling solution. We also realise individual customer requirements.

An intelligent and predictive maintenance concept can minimize manual handling steps around the marking system. Senodis also offers individual service packages tailored to the specific needs of customers. Downtimes are also reduced to a minimum thanks to an optimised design and simple replacement options. Customised packages tailored to the specific needs of the customer round off our service.

In cooperation with