Identification of components in harsh process environments

A transparent process chain and efficient data use and integration improve quality control and uncover potential for process optimisation. This requires the ability to identify and trace each component - even in demanding manufacturing processes. We are your partner at your side when it comes to developing and implementing appropriate solutions.

Laser marking

Counterfeits happen. We make sure you don't pay the price. Whether it's a voided warranty, liability claim, or machine downtime—our marking solutions ensure your originals are identifiable and your operations and customer relationships ...

Learn more

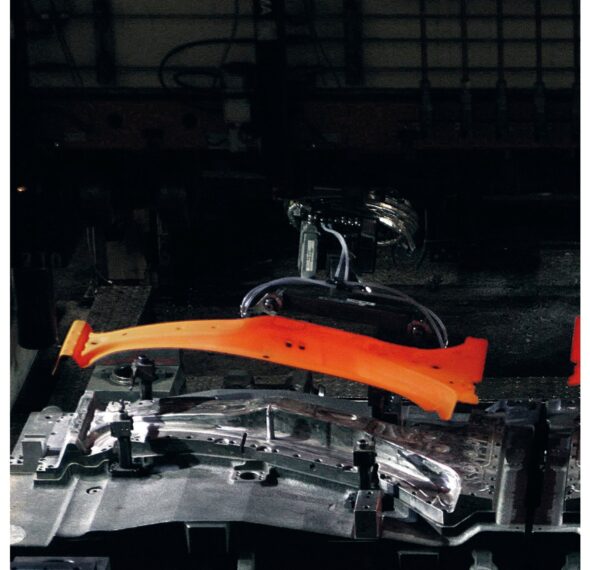

Process optimization in press hardening

Press-hardened components are increasingly used in the automotive industry. Due to the high production numbers, component-specific identification is becoming increasingly important.

Learn more

Part marking for ceramic products

Ceramic products are used where the highest reliability, best quality and enormous resistance are required. The complete traceability of the required components is an elementary part of quality control and the achievement of cost targets.

Learn more

Tracking & tracing in solid forming and case hardening

Demanding manufacturing processes, complex logistics chains and a high variety of materials characterise solid forming. Seamless traceability is essential for energy and material efficiency as well as for ensuring the highest quality standards.

Learn more

Steel bar production

In the production of steel bars, an application in the field of massive forming, rolled steels are separated while hot. The surface temperature after separation is still over 300 °C. After separation, the bars are cooled and bundled.

Learn more

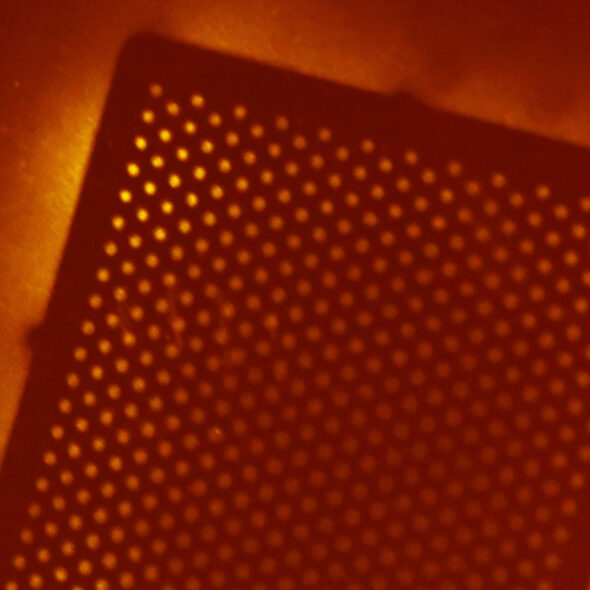

Markings for 3D metrology

Precise marking of the components is required to accurately assess the forming results, for example in press hardening.

Learn more